1.Feeding speed: 2800 CPH

2.Control method: SCM

3.Max Tube loading:10/20/30/ 40 tube

4.Feeding height: 110 ± 10mm

5.Equipment Dimensions: LxWxH:

6.95x1500x1150mm

7.Input voltage: AC110V / 4A

8.Air pressure: 0.5-0 .7 Mpa

9.Total power: 90W

10.Weight: 40Kg)

Key Features:

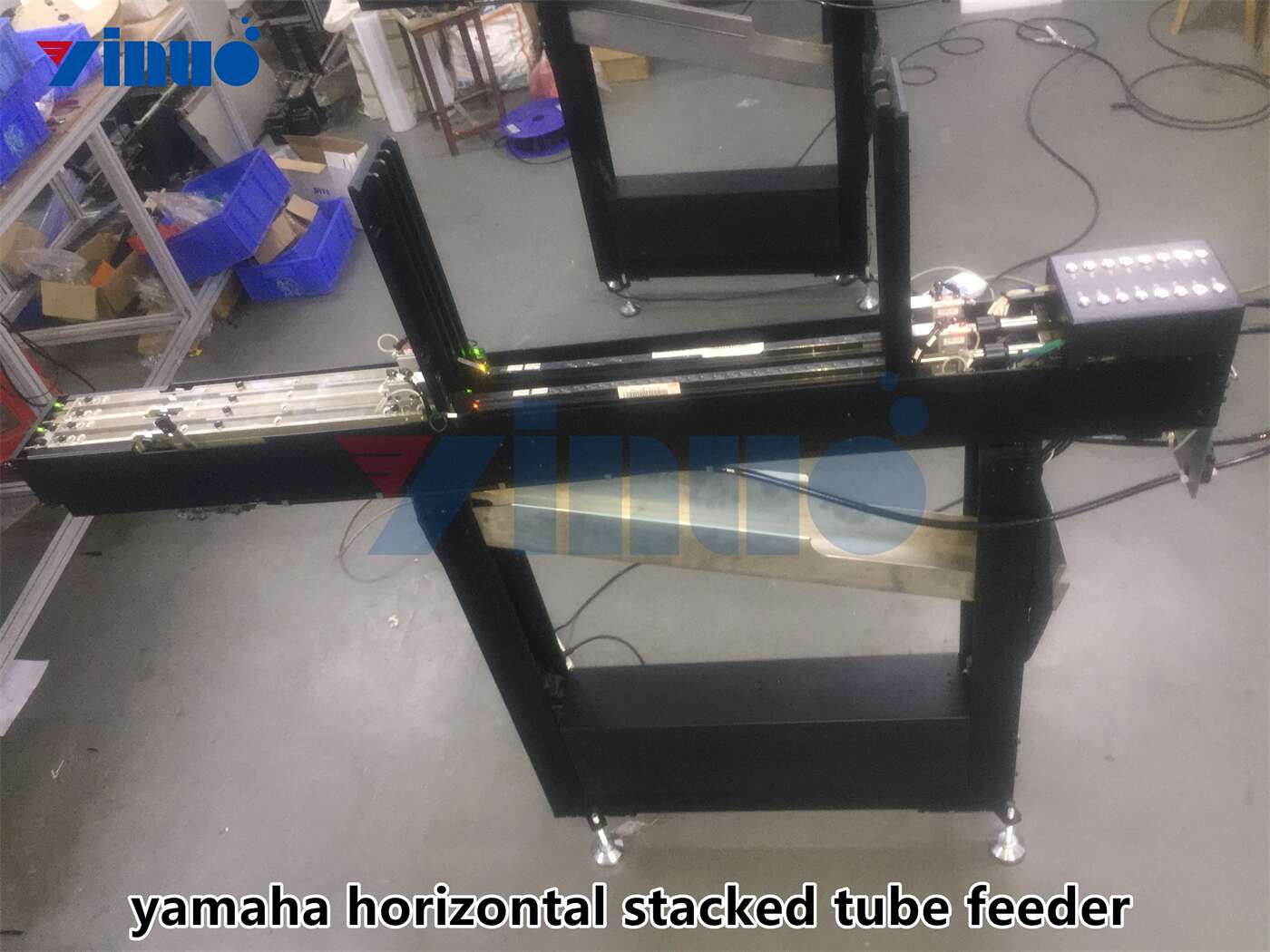

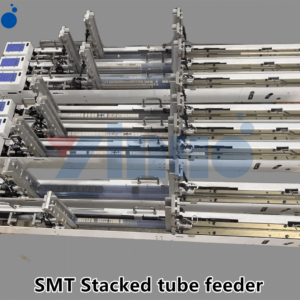

Horizontal Stacked Design:

The feeder holds multiple tubes of components in a horizontal orientation.

Components are stacked in tubes, which are loaded into the feeder for sequential feeding.

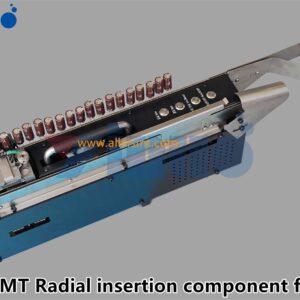

Efficient Feeding:

The feeder pushes components from the tube to the pick-up position using a mechanical or pneumatic mechanism.

It ensures smooth and precise delivery of components to the pick-and-place head.

Space-Saving:

The horizontal stacked design allows multiple tubes to be loaded in a compact space, optimizing the feeder’s footprint.

Compatibility:

These feeders are typically compatible with Yamaha SMT machines, such as the YS or YSM series.

They are used for components that are packaged in tubes rather than reels (e.g., ICs, connectors, or other larger components).

Automation:

The feeder automates the process of advancing components, reducing manual intervention and increasing production efficiency.

Applications:

Used in high-speed PCB assembly lines.

Ideal for components that are not available in tape-and-reel packaging.

Commonly used for ICs, connectors, and other components that are packaged in tubes.

Advantages:

Cost-Effective: Tube feeders are often more economical for low-volume or specialized components.

Flexibility: Can handle a variety of component sizes and shapes.

Ease of Use: Simple to load and operate.

If you are looking for specific models or technical details, Yamaha offers a range of feeders, and the exact specifications depend on the SMT machine model and the type of components being used. Let me know if you’d like more detailed information!