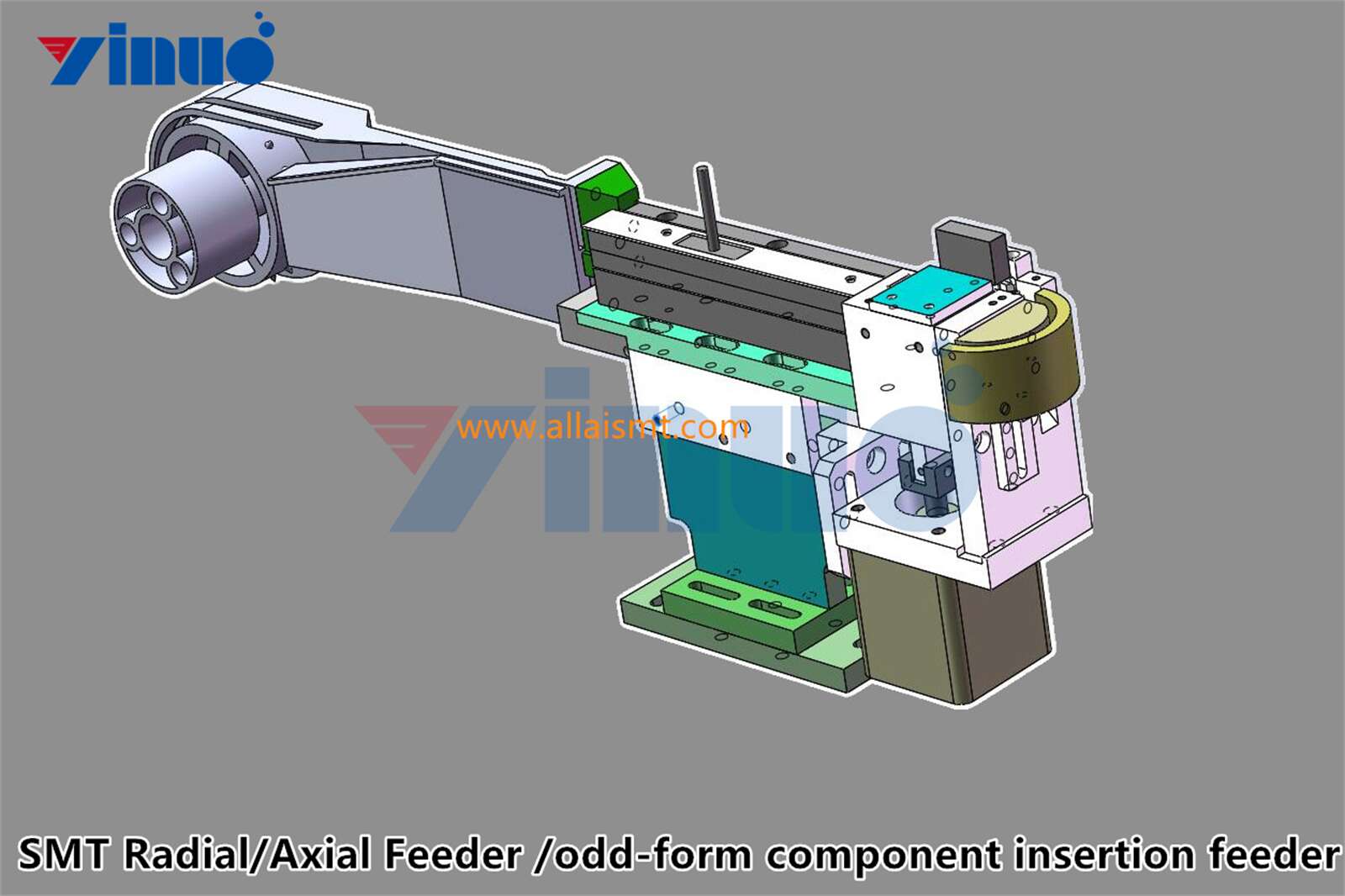

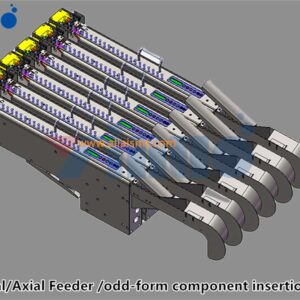

Key Features of Y-RTF101 SMT Feeder:

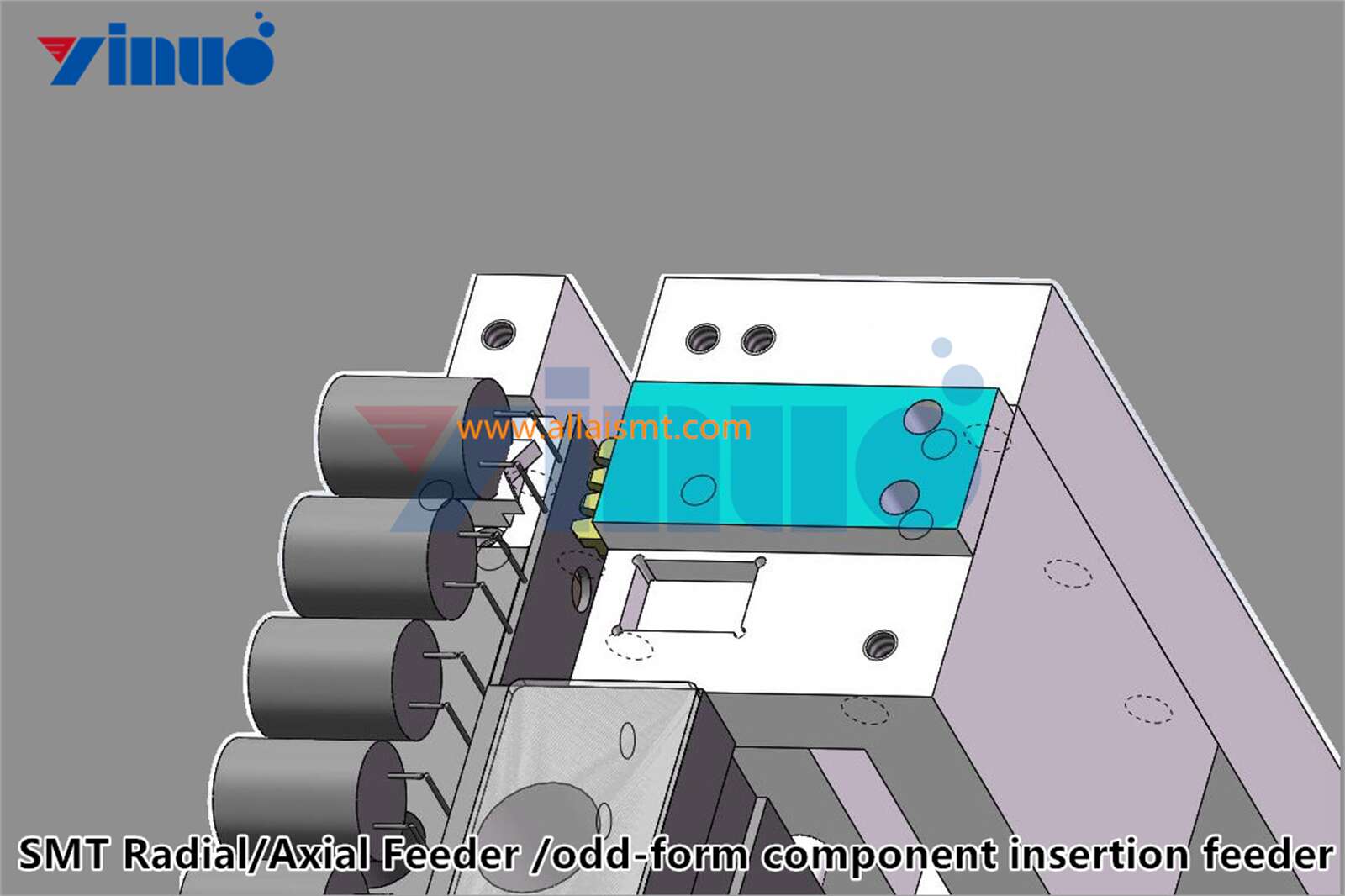

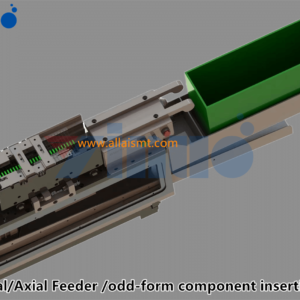

1. Radial and Axial Component Feeding:

- Radial Components: These are components with leads extending radially outward from the body, such as radial capacitors, resistors, and diodes.

- Axial Components: These are components with leads extending axially (in a straight line) from both ends, such as axial resistors, diodes, and inductors.

- The feeder is designed to handle both types efficiently, ensuring proper alignment and orientation for insertion.

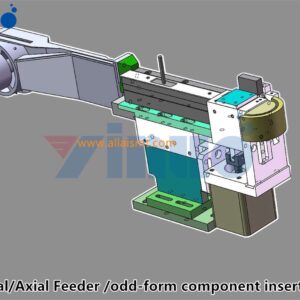

2. Odd-Form Component Handling:

- Supports irregularly shaped components that do not fit standard SMT or through-hole packaging.

- Examples include:

- Large capacitors.

- Transformers.

- Connectors.

- Relays.

- Ensures precise placement or insertion of these components into the PCB.

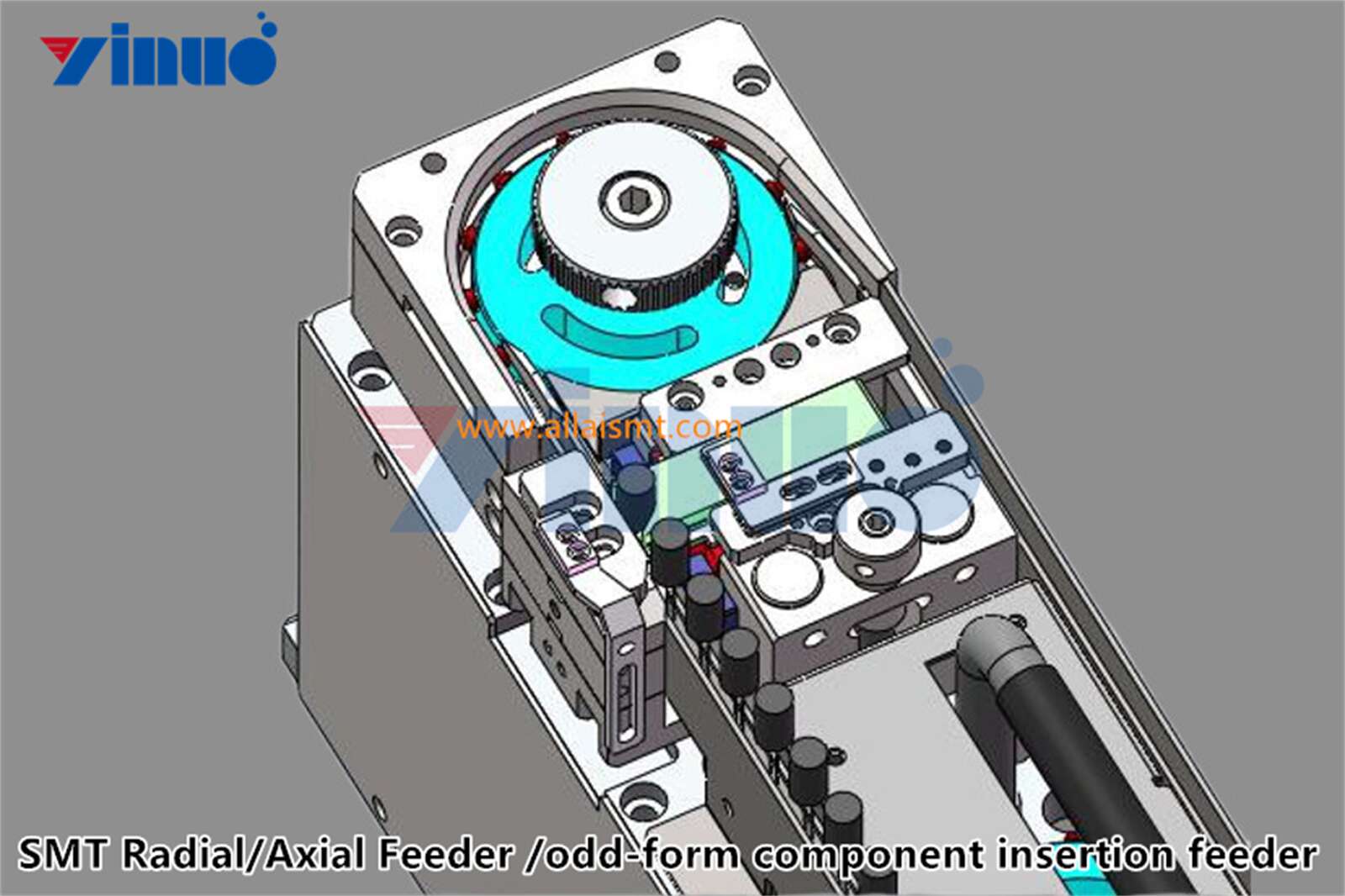

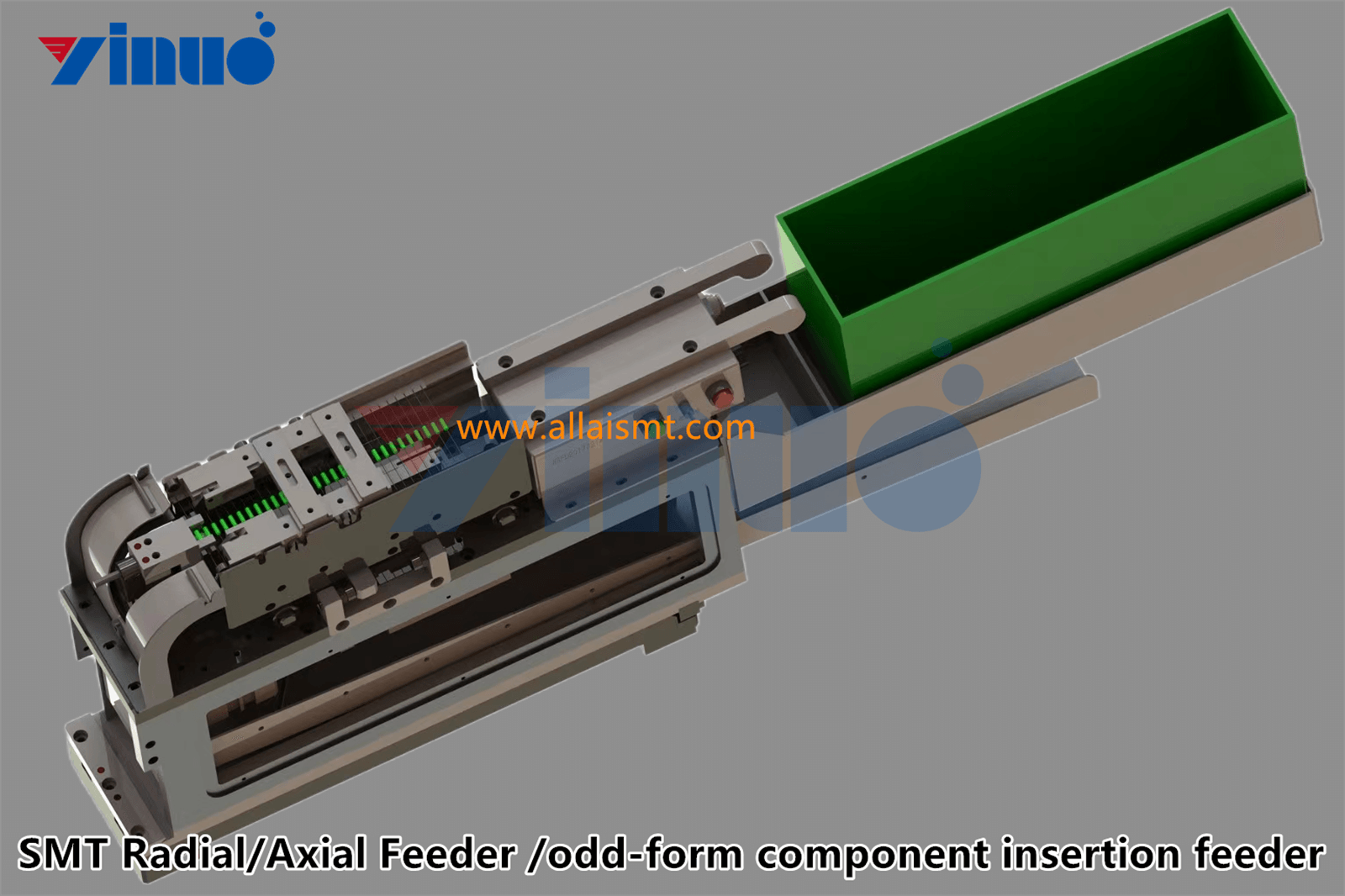

3. Automated Insertion:

- Works with automated insertion machines to place through-hole components into PCBs.

- Reduces manual labor and increases production efficiency.

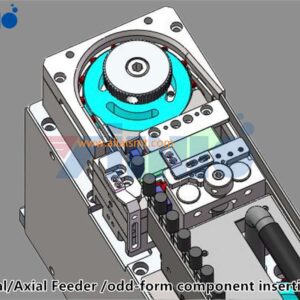

4. High Precision and Reliability:

- Ensures accurate feeding and placement of components, minimizing errors during assembly.

- Designed for high-speed operation in mass production environments.

5. Adjustable Settings:

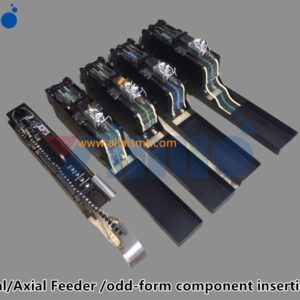

- Can be configured to handle components of various sizes and shapes.

- Compatible with different lead pitches and component dimensions.

6. Durable and Robust Design:

- Built to withstand the demands of high-volume production.

- Ensures long-term reliability and consistent performance.

Applications:

- Through-Hole Technology (THT): Used in PCB assembly lines where through-hole components are required.

- Odd-Form Component Placement: Ideal for components that cannot be placed using standard SMT feeders.

- Hybrid Assembly Lines: Combines SMT and THT processes for mixed-technology PCBs.

Benefits:

- Reduces manual handling of through-hole and odd-form components.

- Increases production speed and efficiency.

- Ensures consistent and accurate placement of components.

If you need more details about its compatibility with specific machines, setup instructions, or supported component types, let me know!