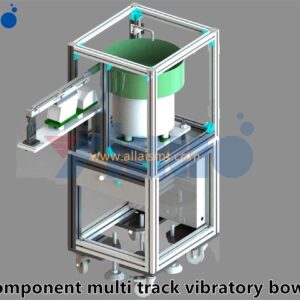

Key Features of Vibratory Bowl Feeders for SMT Machines:

Vibratory Feeding Mechanism:

The feeder uses vibrations to move components along a spiral track inside the bowl.

The vibrations are generated by an electromagnetic drive, which causes the components to move upward and align themselves for proper orientation.

Component Orientation:

The bowl is designed with custom tooling to ensure that components are oriented correctly as they move toward the output chute.

This ensures that the pick-and-place machine can easily pick up the components in the correct position.

Compatibility with SMT Machines:

Vibratory bowl feeders are integrated with SMT machines to supply components directly to the pick-up head.

They are often used for components that cannot be fed using traditional tape-and-reel or tube feeders.

Customizable Design:

The bowl and track can be customized to handle specific component shapes, sizes, and orientations.

This makes vibratory feeders versatile for a wide range of components.

High-Speed Feeding:

Vibratory feeders are capable of feeding components at high speeds, keeping up with the demands of modern SMT machines.

Durability:

Made from robust materials like stainless steel or aluminum to withstand continuous operation in industrial environments.

Applications in SMT:

Feeding loose or bulk components such as:

Connectors

Odd-shaped ICs

LEDs

Capacitors or resistors not packaged in reels

Custom or irregularly shaped components

Used in scenarios where tape-and-reel or tube packaging is not practical or cost-effective.

Advantages:

Cost-Effective:

Ideal for components that are not available in standard packaging formats.

Flexibility:

Can handle a wide variety of component shapes and sizes.

Automation:

Reduces manual handling of components, improving efficiency and accuracy.

High Throughput:

Capable of feeding components at a rate that matches the speed of modern SMT machines.

Limitations:

Initial Setup:

Requires custom tooling and setup for specific components, which can be time-consuming and costly.

Noise:

Vibratory feeders can generate noise during operation.

Component Damage:

Fragile components may be damaged due to vibrations or collisions during feeding.

Integration with SMT Machines:

Vibratory bowl feeders are typically connected to SMT machines via a conveyor or chute system.

Sensors are often used to monitor the component supply and ensure a continuous flow to the pick-and-place head.

Alternatives:

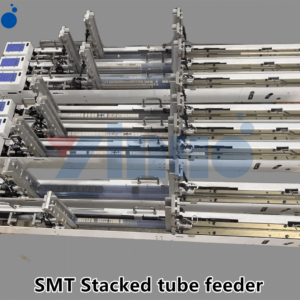

Tape-and-Reel Feeders: For standard components.

Tube Feeders: For ICs and other components packaged in tubes.

Tray Feeders: For larger or delicate components.

Vibratory bowl feeders are an excellent solution for handling non-standard components in SMT assembly lines. If you need more details about specific models or manufacturers, feel free to ask!