1) Feeder Dimension (L*W*H): 550*110*130mm

2) Tape Component dimension: 2*2*3-15*15*30mm

3). Distance Transport Hole: 12.7mm / 15mm

4). Distance Transport hole to cutting edge: 11mm

5). Tape Component Height: Max. 30mm

6). Component Body Diameter: Max. 15mm

7). Speed: 0.8 Sec./pcs

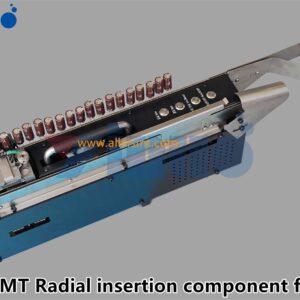

Key Features of THT SMT Radial Insertion Component Feeders:

Radial Component Handling:

Designed specifically for radial-leaded components, where the leads extend outward from the body of the component.

Common components include electrolytic capacitors, ceramic capacitors, resistors, and LEDs.

Component Feeding Mechanism:

Components are typically supplied in tape-and-reel or ammo pack packaging.

The feeder advances the tape or ammo pack to present the next component to the insertion head.

The feeder cuts the leads to the desired length and prepares the component for insertion.

Lead Cutting and Forming:

The feeder includes mechanisms to cut and form the leads of the component to match the PCB’s hole spacing.

Lead forming ensures proper alignment and secure placement in the PCB.

High-Speed Automation:

Radial insertion feeders are designed for high-speed operation, enabling rapid placement of through-hole components.

They are integrated into radial insertion machines, which can insert thousands of components per hour.

Precision Placement:

The feeder ensures precise alignment of components for accurate insertion into the PCB.

Sensors and alignment mechanisms are used to verify the position and orientation of components.

Integration with SMT and THT Lines:

These feeders are part of hybrid assembly lines that combine SMT and THT processes.

They are used in applications where through-hole components are required for mechanical strength or specific electrical properties.

Applications:

Consumer Electronics: For assembling products like televisions, radios, and home appliances.

Automotive Electronics: Used in PCBs for automotive applications where through-hole components are preferred for durability.

Industrial Equipment: For assembling PCBs in industrial control systems and power supplies.

LED Lighting: For inserting LEDs and other radial components in lighting products.

Advantages:

High Efficiency:

Automates the insertion of radial components, reducing manual labor and increasing throughput.

Consistency:

Ensures uniform lead cutting, forming, and placement, improving assembly quality.

Cost-Effective:

Reduces assembly time and labor costs for high-volume production.

Versatility:

Can handle a wide range of radial components with different sizes and lead configurations.

Limitations:

Initial Cost:

Radial insertion machines and feeders can be expensive to purchase and set up.

Component Packaging:

Requires components to be supplied in tape-and-reel or ammo pack formats, which may not be suitable for all components.

Limited to Radial Components:

Cannot handle axial-leaded components or SMT components.

How It Works:

Component Loading:

Radial components are loaded into the feeder in tape-and-reel or ammo pack form.

Feeding:

The feeder advances the tape or ammo pack to position the next component for processing.

Lead Cutting and Forming:

The feeder cuts the leads to the desired length and forms them to match the PCB’s hole spacing.

Insertion:

The insertion head picks up the component and inserts it into the PCB.

Lead Clinching:

After insertion, the leads are clinched (bent) on the underside of the PCB to secure the component in place.

Integration with SMT Lines:

In modern assembly lines, THT radial insertion machines are often used alongside SMT machines to handle mixed-technology PCBs.

SMT machines place surface-mount components, while radial insertion machines handle through-hole components.

Leading Manufacturers:

Some of the leading manufacturers of radial insertion machines and feeders include:

Panasonic: Known for their high-speed radial insertion machines.

Universal Instruments: Offers versatile radial insertion systems.

Juki: Provides solutions for both SMT and THT assembly.

Fuji: Known for advanced automation in PCB assembly.

If you need more details about specific machines, feeders, or their integration into your production line, let me know!