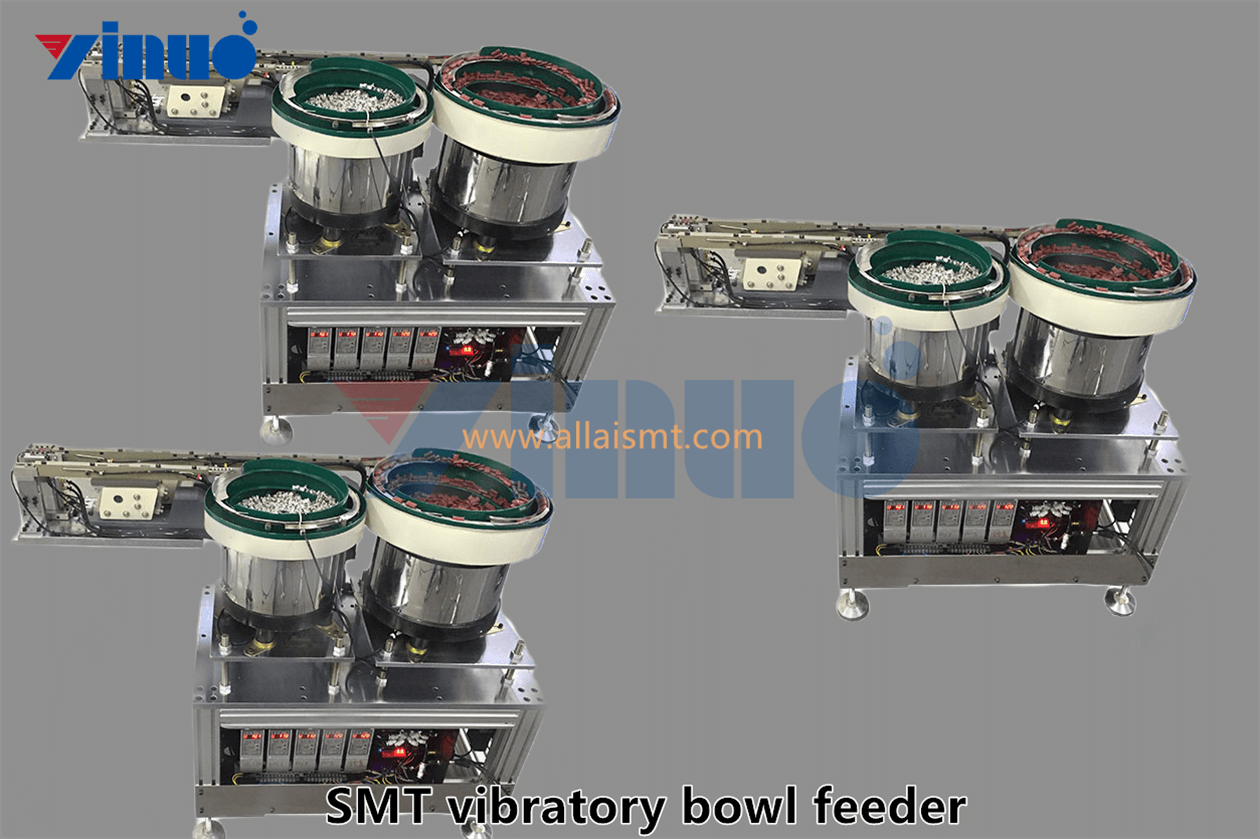

1) Feeder Dimension (L*W*H): 760*460*910mm

2) Controle By: Coil Motor

3) Power Supply 100/220V

4) Air Pressure & Consumption: 0.4-0.6 Mpa

5). Speed: 0.8 Sec./pcs

6). Feeder Weight: Approx. 150 KG

7). One orbits One vibrating bowls

8). Compatible Electronic Components Type:1

What is an SMT Vibratory Bowl Feeder?

A vibratory bowl feeder uses vibrations to move components along a spiral track inside a bowl. The components are oriented and aligned as they move toward the output chute, where they are picked up by the SMT machine or transferred to another feeder system.

Key Features of SMT Vibratory Bowl Feeders:

Vibratory Feeding Mechanism:

Vibrations generated by an electromagnetic drive move components along the bowl’s spiral track.

The vibrations ensure smooth and consistent feeding of components.

Component Orientation:

The bowl is custom-designed to orient components correctly as they move toward the output.

This ensures that components are in the proper position for pick-and-place machines.

Handling Odd-Shaped Components:

Ideal for irregularly shaped components that cannot be fed using standard tape-and-reel or tube feeders.

Examples include connectors, LEDs, large capacitors, and custom components.

High-Speed Operation:

Designed to keep up with the high-speed demands of modern SMT assembly lines.

Ensures a continuous supply of components to the pick-and-place machine.

Customizable Design:

The bowl and track can be customized to handle specific component shapes, sizes, and orientations.

Adjustable settings allow for flexibility in feeding different types of components.

Durable and Reliable:

Built with robust materials like stainless steel or aluminum to withstand continuous operation in industrial environments.

Designed for long-term reliability and minimal maintenance.

Applications of SMT Vibratory Bowl Feeders:

Odd-Form Component Feeding:

Used for components that are not available in standard packaging formats (e.g., tape-and-reel or trays).

Examples include connectors, relays, transformers, and custom parts.

Through-Hole Technology (THT):

Often used in hybrid assembly lines that combine SMT and THT processes.

LED and Connector Placement:

Commonly used for feeding LEDs, connectors, and other components that require precise orientation.

PCB Assembly:

Ensures efficient feeding of components for automated PCB assembly processes.

Advantages of SMT Vibratory Bowl Feeders:

Automation:

Reduces manual handling of components, increasing production efficiency.

Flexibility:

Can handle a wide variety of component shapes and sizes.

Cost-Effective:

Ideal for components that are not available in standard packaging, saving costs on custom packaging.

High Precision:

Ensures accurate feeding and orientation of components, minimizing errors during assembly.

Continuous Operation:

Provides a steady supply of components, reducing downtime and improving throughput.

Limitations:

Initial Setup:

Requires custom tooling and setup for specific components, which can be time-consuming and costly.

Noise:

Vibratory feeders can generate noise during operation.

Component Damage:

Fragile components may be damaged due to vibrations or collisions during feeding.

How It Works:

Loading:

Components are loaded into the bowl in bulk.

Vibration:

Electromagnetic vibrations move the components along the spiral track.

Orientation:

The bowl’s design ensures that components are oriented correctly as they move toward the output.

Feeding:

Components are fed to the pick-and-place machine or another feeder system for placement on the PCB.

Conclusion:

SMT Vibratory Bowl Feeders are an essential tool for handling bulk and odd-shaped components in automated PCB assembly lines. Their ability to orient and feed components efficiently makes them a valuable addition to any SMT production process. If you need more details about specific models, manufacturers, or integration with SMT machines, feel free to ask!