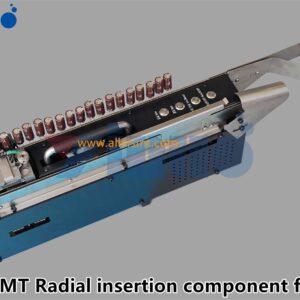

Radial Feeders

Overview of SMT Radial Feeders

Radial feeders are used to handle radial-leaded components, such as:

- Radial capacitors (e.g., electrolytic capacitors).

- Radial resistors.

- LEDs.

- Diodes.

- Other through-hole components with radial lead configurations.

These feeders are essential for Through-Hole Technology (THT) or hybrid assembly lines, where both SMT and THT components are used.

Key Features of SMT Radial Feeders for JUKI, ASM, YAMAHA, and Panasonic Machines

- Radial Component Feeding:

- Designed to handle radial-leaded components supplied in tape-and-reel or ammo pack packaging.

- Ensures smooth and continuous feeding of components to the pick-and-place machine.

- Lead Cutting and Forming:

- The feeder cuts the leads of radial components to the desired length.

- Lead forming ensures the component fits perfectly into the PCB’s through-holes.

- High-Speed Operation:

- Compatible with high-speed pick-and-place machines from JUKI, ASM, YAMAHA, and Panasonic.

- Ensures a steady supply of components to avoid production delays.

- Precision Placement:

- Ensures accurate alignment and positioning of components for the pick-and-place head.

- Reduces errors and improves assembly quality.

- Compatibility:

- Designed to integrate seamlessly with pick-and-place machines from:

- JUKI: Known for their flexible and high-speed SMT machines.

- ASM: Advanced SMT solutions for high-volume production.

- YAMAHA: Reliable and versatile SMT machines.

- Panasonic: High-speed modular placement machines.

- Can handle a wide range of radial component sizes and lead pitches.

- Designed to integrate seamlessly with pick-and-place machines from:

- Durable and Robust Design:

- Built with robust materials to withstand the demands of high-volume production environments.

- Designed for long-term reliability and minimal maintenance.

- Customizable Settings:

- Adjustable to handle components of various sizes, shapes, and lead configurations.

- Compatible with different lead pitches and component dimensions.

Applications of SMT Radial Feeders

- Through-Hole Technology (THT):

- Used in assembly lines where through-hole components are required for mechanical strength or specific electrical properties.

- Hybrid Assembly Lines:

- Combines SMT and THT processes for mixed-technology PCBs.

- Consumer Electronics:

- Commonly used in products like televisions, radios, and home appliances.

- Automotive Electronics:

- Ideal for assembling PCBs in automotive applications where through-hole components are preferred for durability.

- Industrial Equipment:

- Used in PCBs for industrial control systems, power supplies, and other applications.

Advantages of SMT Radial Feeders

- Automation:

- Reduces manual handling of radial components, increasing production efficiency.

- Consistency:

- Ensures uniform lead cutting, forming, and placement, improving assembly quality.

- High Throughput:

- Capable of feeding and placing components at high speeds, keeping up with modern production demands.

- Flexibility:

- Can handle a variety of radial components with different sizes and lead configurations.

- Cost-Effective:

- Reduces labor costs and assembly time for high-volume production.

How It Works

- Component Loading:

- Radial components are loaded into the feeder in tape-and-reel or ammo pack form.

- Feeding:

- The feeder advances the tape or ammo pack to position the next component for processing.

- Lead Cutting and Forming:

- The feeder cuts the leads to the desired length and forms them to match the PCB’s hole spacing.

- Pick-and-Place:

- The pick-and-place machine picks up the component and inserts it into the PCB.

- Lead Clinching:

- After insertion, the leads are clinched (bent) on the underside of the PCB to secure the component in place.

Compatibility with JUKI, ASM, YAMAHA, and Panasonic Machines

- JUKI:

- JUKI pick-and-place machines are known for their flexibility and high-speed operation.

- Radial feeders for JUKI machines are designed to integrate seamlessly with their THT and hybrid assembly lines.

- ASM:

- ASM (formerly Siemens) machines are used in high-volume production environments.

- Radial feeders for ASM machines are optimized for precision and speed.

- YAMAHA:

- YAMAHA SMT machines are versatile and reliable, making them ideal for hybrid assembly lines.

- Radial feeders for YAMAHA machines are designed to handle a wide range of component sizes and lead configurations.

- Panasonic:

- Panasonic machines are known for their high-speed modular placement capabilities.

- Radial feeders for Panasonic machines are built to match their high-speed operation and precision requirements.

Limitations

- Initial Cost:

- Radial feeders and insertion machines can be expensive to purchase and set up.

- Component Packaging:

- Requires components to be supplied in tape-and-reel or ammo pack formats.

- Limited to Radial Components:

- Cannot handle axial-leaded components or SMT components.

Leading Manufacturers of SMT Radial Feeders

- Panasonic:

- Offers high-speed radial insertion machines and feeders.

- JUKI:

- Provides solutions for both SMT and THT assembly.

- ASM Assembly Systems:

- Known for advanced automation in PCB assembly.

- YAMAHA:

- Reliable and versatile feeders for hybrid assembly lines.

Conclusion

An SMT Radial Feeder is an essential tool for automating the placement of radial-leaded components in PCB assembly. Its ability to handle lead cutting, forming, and precise placement makes it a valuable addition to any production line, especially for hybrid or through-hole assembly processes. These feeders are compatible with leading pick-and-place machines from JUKI, ASM, YAMAHA, and Panasonic, ensuring seamless integration and high production efficiency.

If you need more details about specific models, configurations, or integration with your pick-and-place machine, feel free to ask!