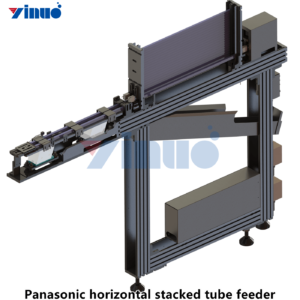

1.Feeding speed: 2800 CPH

2.Control method: SCM

3.Max Tube loading:10/20/30/ 40 tube

4.Feeding height: 110 ± 10mm

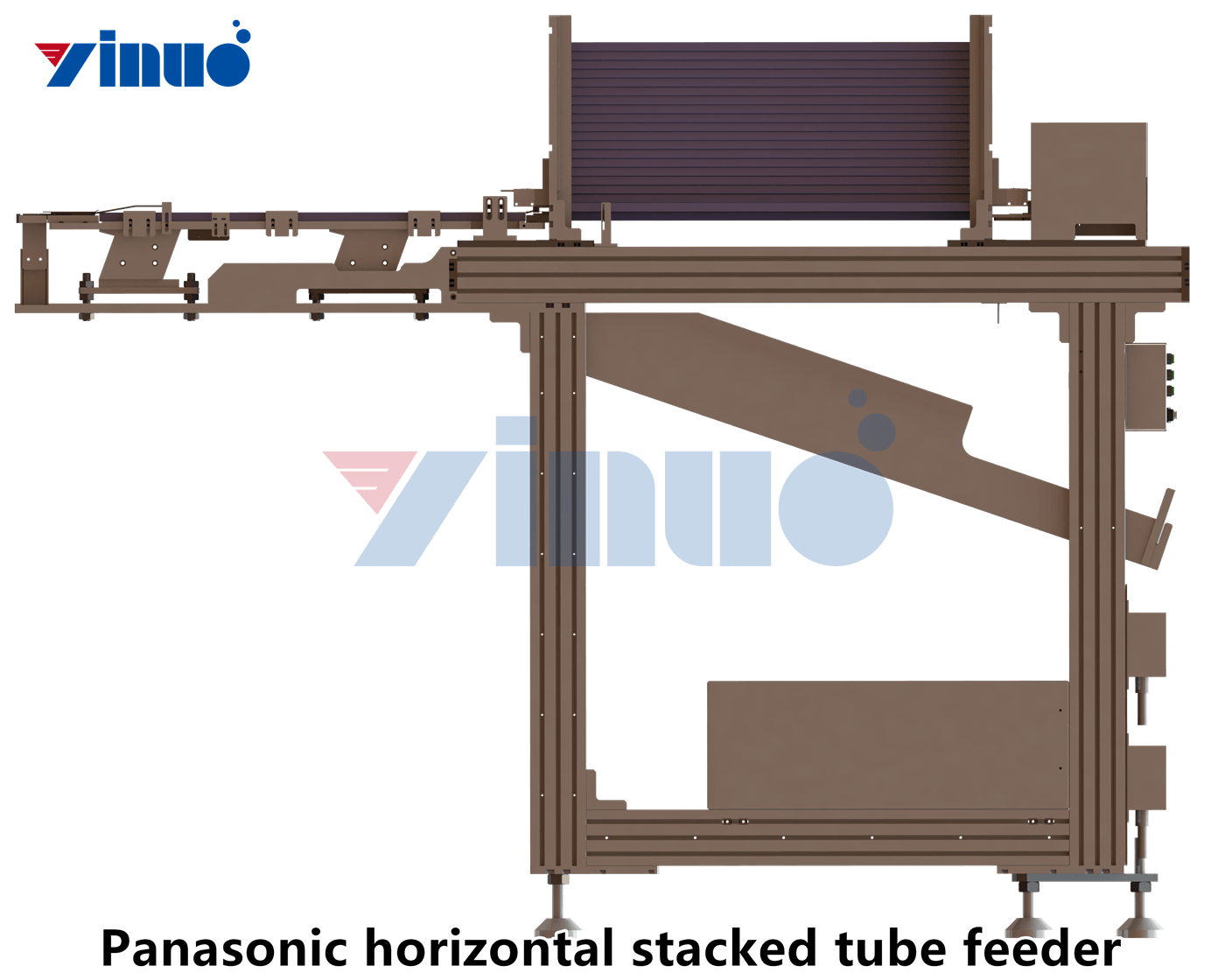

5.Equipment Dimensions: LxWxH:

6.95x1500x1150mm

7.Input voltage: AC110V / 4A

8.Air pressure: 0.5-0 .7 Mpa

9.Total power: 90W

10.Weight: 40Kg)

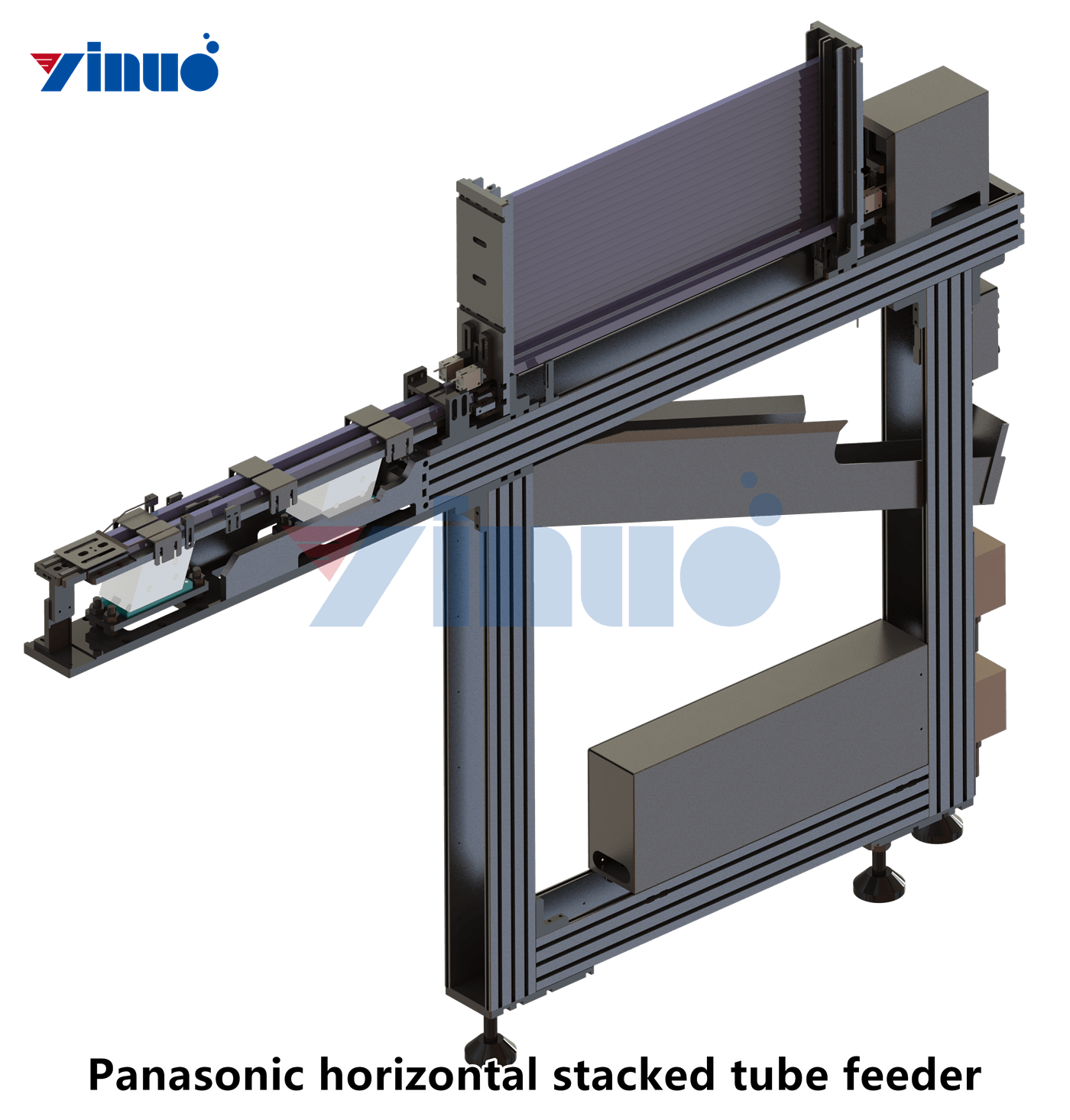

Key Features of Panasonic Horizontal Stacked Tube Feeder:

Horizontal Stacked Design:

The feeder holds multiple tubes of components in a horizontal orientation.

Tubes are stacked on top of each other, allowing for efficient use of space and easy loading.

Component Feeding:

Components are pushed out of the tube one at a time to the pick-up position using a mechanical or pneumatic pusher.

The feeder ensures smooth and precise delivery of components to the pick-and-place head.

Compatibility:

Designed to work seamlessly with Panasonic SMT machines, such as the Panasonic NPM (Next Production Modular) series or other Panasonic pick-and-place systems.

Supports a wide range of component sizes and types.

High Efficiency:

The stacked design allows for multiple tubes to be loaded at once, reducing downtime for reloading.

Ensures continuous feeding of components to keep up with the high-speed operation of Panasonic SMT machines.

Durable and Reliable:

Built with robust materials to withstand the demands of high-volume production environments.

Designed for long-term reliability and minimal maintenance.

Flexibility:

Can handle a variety of component types, including ICs, connectors, and other through-hole or surface-mount components that are packaged in tubes.

Suitable for both small and large production runs.

Applications:

PCB Assembly: Used in SMT lines for placing components that are not available in tape-and-reel packaging.

IC Placement: Ideal for feeding integrated circuits (ICs) and other components that are typically packaged in tubes.

Connector Placement: Commonly used for connectors and other odd-shaped components.

Advantages:

Space-Saving:

The horizontal stacked design optimizes space on the feeder platform.

Reduced Downtime:

Multiple tubes can be loaded simultaneously, reducing the need for frequent reloading.

Cost-Effective:

Suitable for components that are not available in tape-and-reel packaging, saving costs on custom packaging.

Ease of Use:

Simple to load and operate, with minimal training required for operators.

Limitations:

Component Packaging:

Only works with components packaged in tubes, which may not be suitable for all types of components.

Speed:

Feeding speed may be slower compared to tape-and-reel feeders, depending on the component type and machine configuration.

Setup Time:

Initial setup and alignment of the tubes may take longer compared to other feeder types.

Integration with Panasonic SMT Machines:

The horizontal stacked tube feeder is designed to integrate seamlessly with Panasonic SMT machines, ensuring smooth operation and high placement accuracy.

It is often used in combination with other feeder types (e.g., tape-and-reel feeders, tray feeders) to handle a wide variety of components in a single production line.

Common Panasonic SMT Machines Compatible with Tube Feeders:

Panasonic NPM Series: High-speed modular placement machines.

Panasonic CM Series: Compact and versatile placement machines.

Panasonic AM Series: Designed for odd-shaped and large components.

Conclusion:

The Panasonic Horizontal Stacked Tube Feeder is an essential tool for SMT assembly lines that need to handle components packaged in tubes. Its efficient design, compatibility with Panasonic machines, and ability to handle a wide range of components make it a valuable addition to any PCB assembly process. If you need more details about specific models or configurations, feel free to ask!