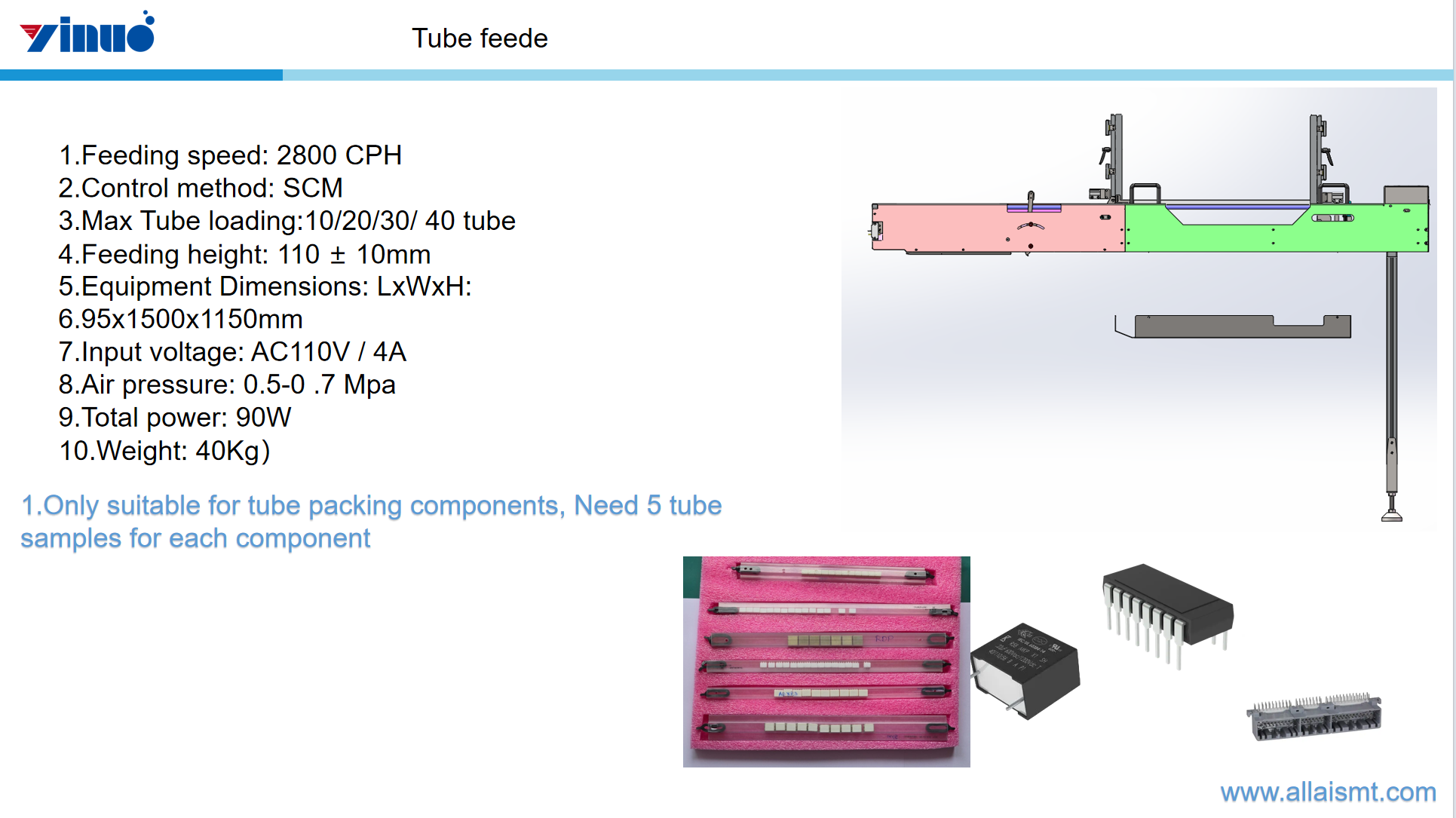

Tube feede

Key Features of FUJI Horizontal Stacked Tube Feeder

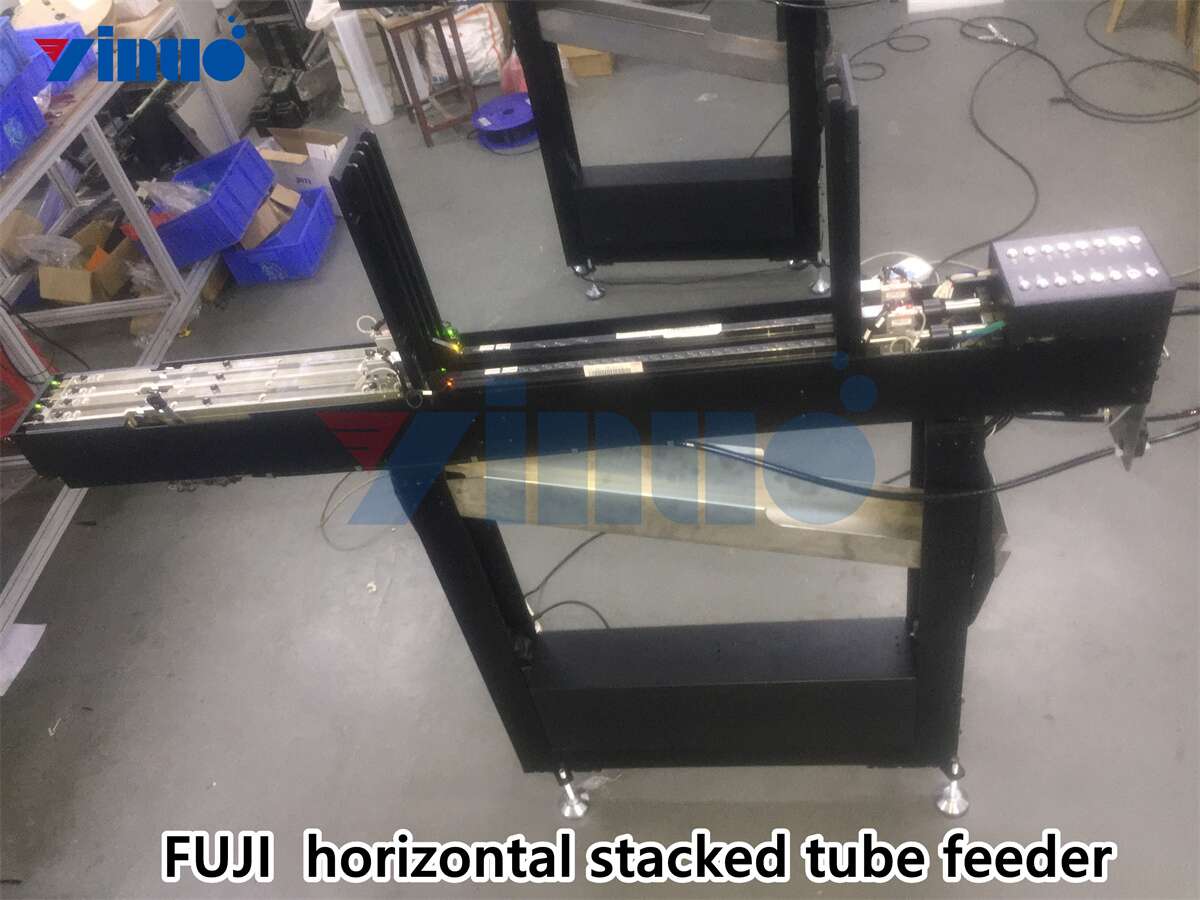

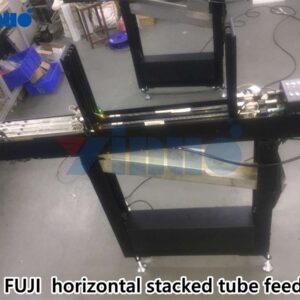

- Horizontal Tube Feeding:

- Components are fed from horizontally stacked tubes, which are aligned for smooth feeding.

- The horizontal orientation ensures stability and efficient feeding of components.

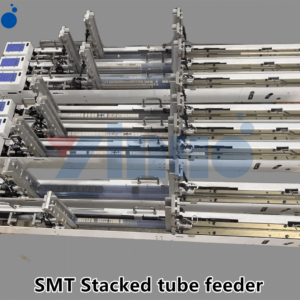

- Stacked Tube Design:

- Multiple tubes can be stacked in the feeder, allowing for uninterrupted feeding.

- When one tube is empty, the feeder automatically switches to the next tube in the stack, minimizing downtime.

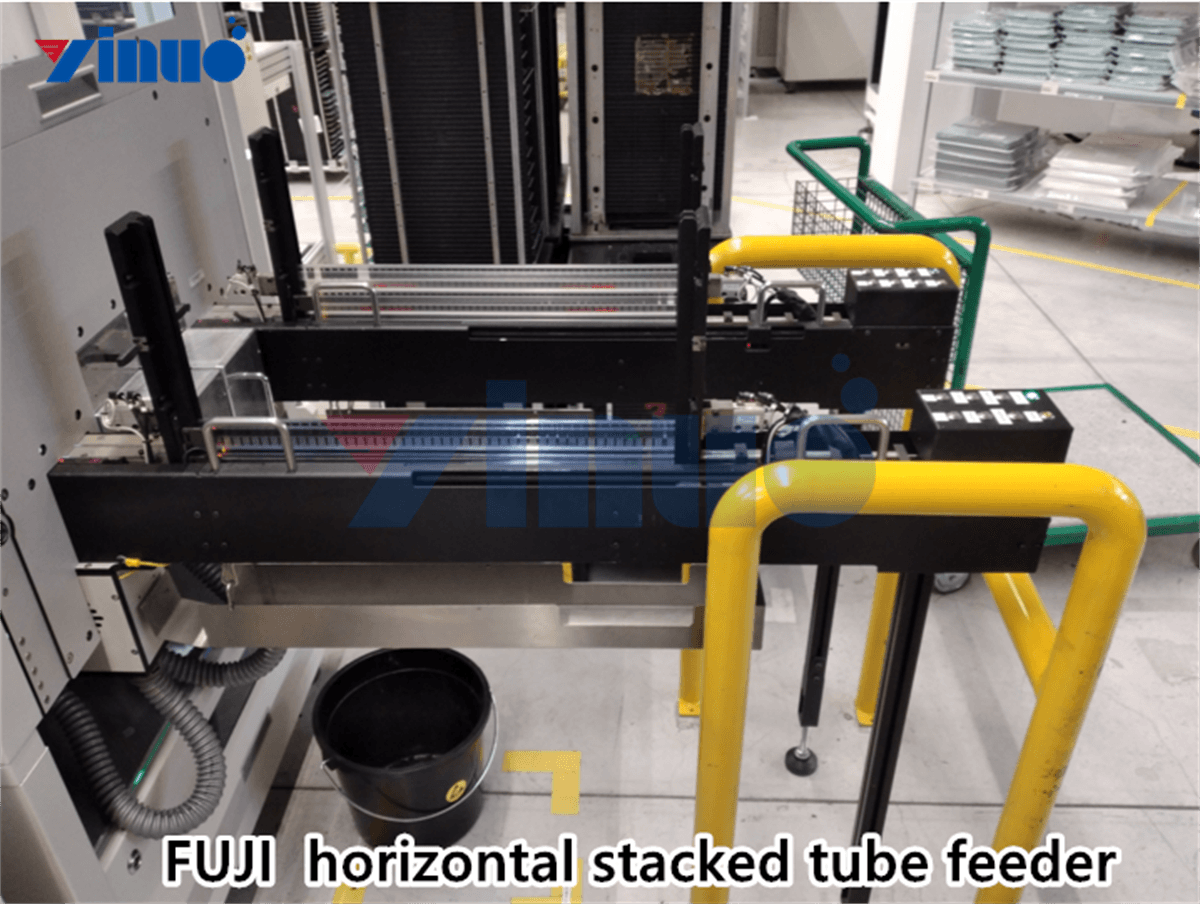

- High-Speed Operation:

- Designed to keep up with the high-speed demands of FUJI pick-and-place machines.

- Ensures a steady supply of components to avoid production delays.

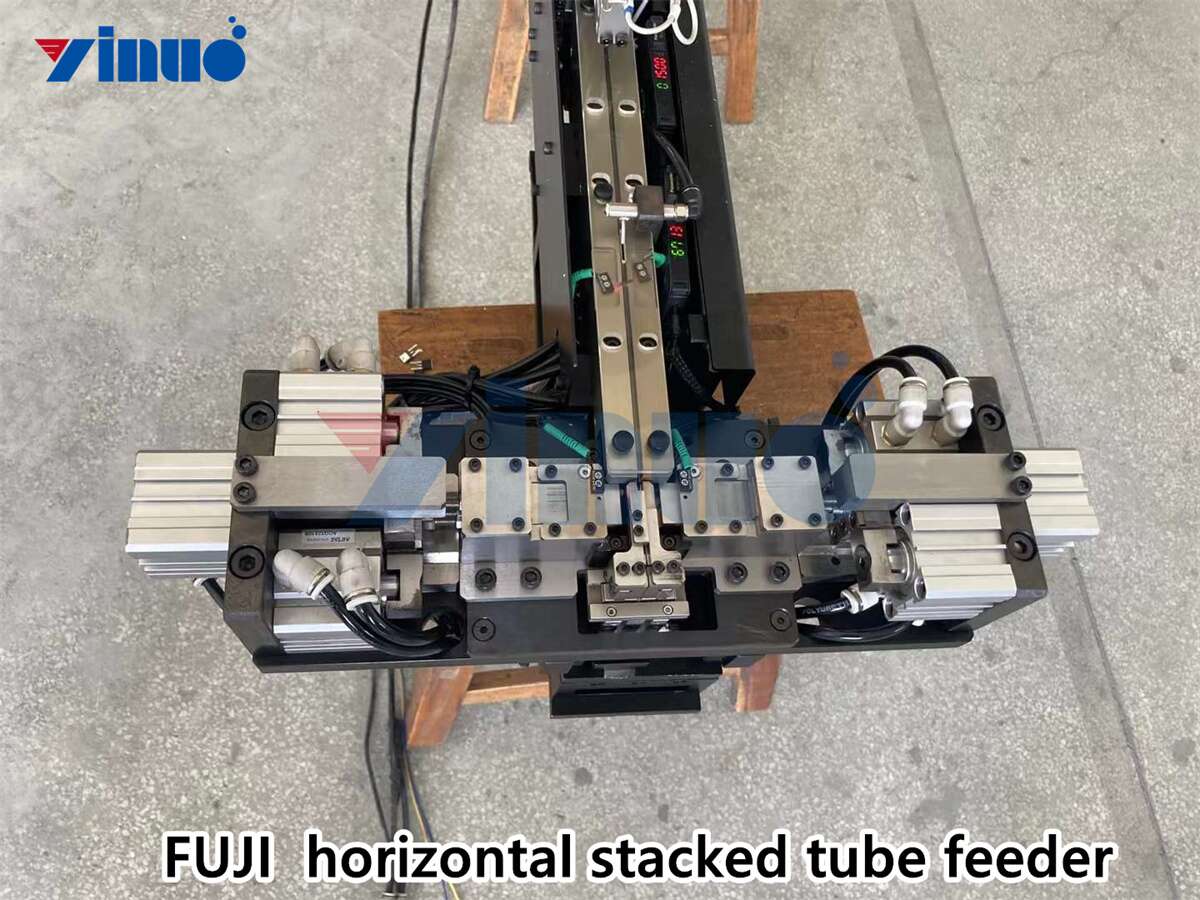

- Automatic Component Alignment:

- The feeder ensures that components are properly aligned and oriented before being picked up by the machine.

- Reduces errors and improves placement accuracy.

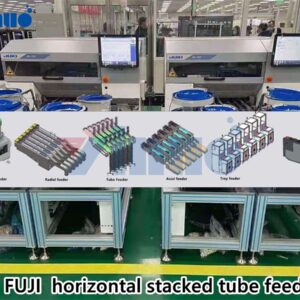

- Compatibility:

- Specifically designed for FUJI pick-and-place machines, such as the FUJI NXT, AIMEX, and other FUJI SMT platforms.

- Can handle a wide range of component sizes and types that are supplied in tubes.

- Durable and Reliable:

- Built with high-quality materials to withstand continuous operation in industrial environments.

- Designed for long-term reliability and minimal maintenance.

- Adjustable Settings:

- Can be adjusted to accommodate different tube sizes and component dimensions.

- Flexible enough to handle a variety of component types.

- Compact Design:

- The horizontal stacked configuration saves space on the production floor while maximizing feeding capacity.

Applications of FUJI Horizontal Stacked Tube Feeder

- IC Feeding:

- Ideal for feeding integrated circuits (ICs) that are packaged in tubes.

- Commonly used for components like microcontrollers, memory chips, and power ICs.

- Connector Feeding:

- Suitable for connectors and other odd-shaped components that are supplied in tubes.

- Odd-Form Components:

- Handles components that are not suitable for tape-and-reel or tray packaging.

- High-Mix, Low-Volume Production:

- Useful in production environments where a variety of components need to be fed efficiently.

- Automotive and Industrial Electronics:

- Often used in the assembly of PCBs for automotive and industrial applications.

Advantages of FUJI Horizontal Stacked Tube Feeder

- Continuous Feeding:

- The stacked tube design allows for uninterrupted feeding, reducing downtime and increasing productivity.

- High Precision:

- Ensures accurate alignment and orientation of components, minimizing placement errors.

- Flexibility:

- Can handle a wide range of component sizes and types, making it suitable for various applications.

- Space-Saving Design:

- The horizontal orientation and stacked configuration save space on the production floor.

- Cost-Effective:

- Reduces manual handling of components, improving efficiency and lowering labor costs.

- Seamless Integration:

- Designed to work seamlessly with FUJI pick-and-place machines, ensuring compatibility and ease of use.

How It Works

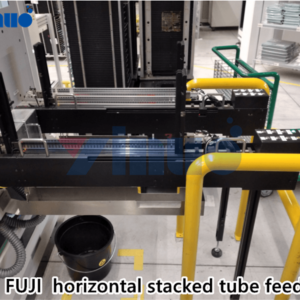

- Loading:

- Tubes containing components are loaded into the feeder in a horizontal orientation.

- Multiple tubes can be stacked to allow for continuous feeding.

- Feeding:

- Components are pushed out of the tube one at a time using a mechanical or pneumatic mechanism.

- The feeder ensures that components are properly aligned and oriented.

- Switching Tubes:

- When one tube is empty, the feeder automatically switches to the next tube in the stack.

- Pick-and-Place:

- The FUJI pick-and-place machine picks up the components from the feeder and places them on the PCB.

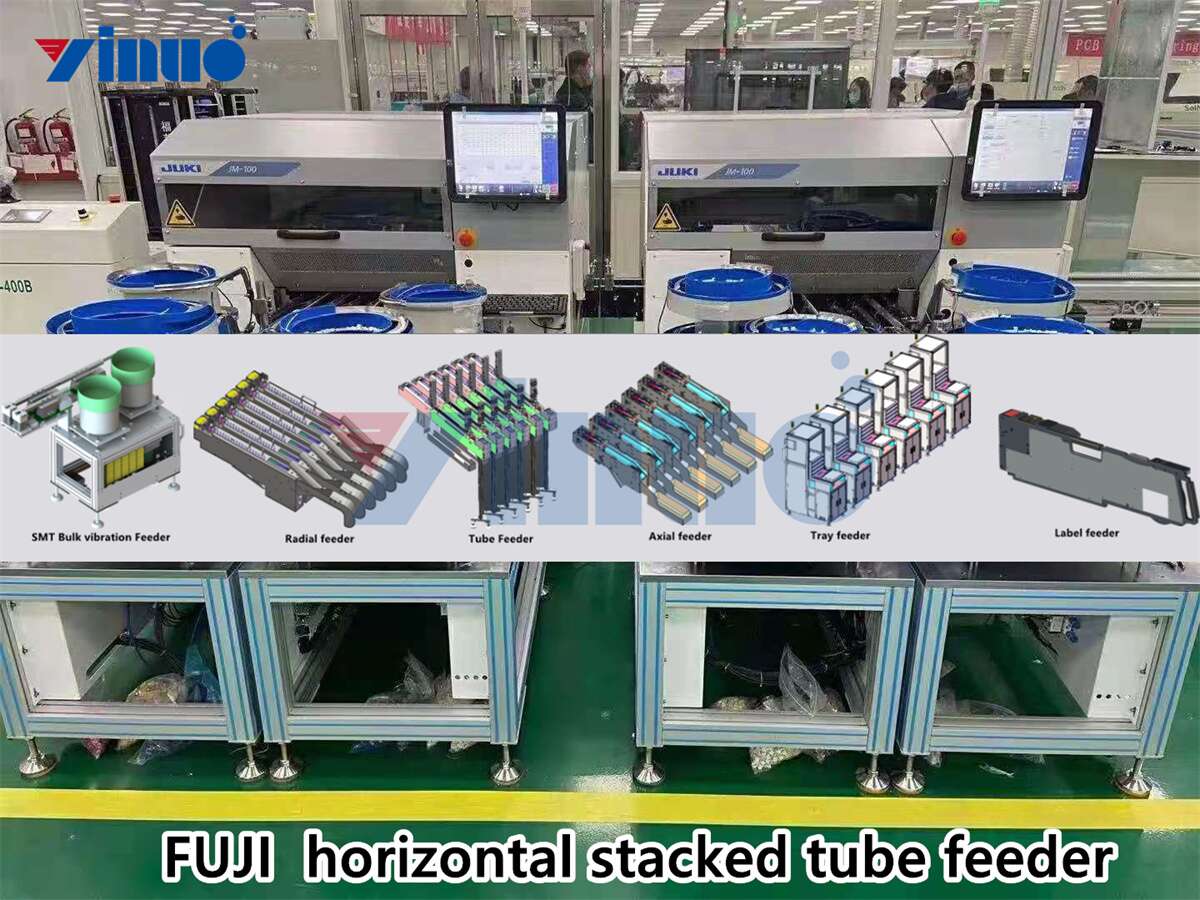

FUJI Pick-and-Place Machines Compatible with Horizontal Stacked Tube Feeders

- FUJI NXT Series:

- High-speed modular pick-and-place machines designed for flexibility and precision.

- The horizontal stacked tube feeder integrates seamlessly with the NXT platform.

- FUJI AIMEX Series:

- Versatile pick-and-place machines for high-mix, low-volume production.

- Ideal for handling odd-form components and tube-fed parts.

- FUJI XP Series:

- High-performance machines for large-scale production.

- Compatible with tube feeders for ICs and connectors.

- Other FUJI Platforms:

- The feeder can be adapted for use with other FUJI SMT platforms, depending on the specific requirements.

Limitations

- Tube Packaging Required:

- Components must be supplied in tubes, which may not be suitable for all component types.

- Initial Setup:

- Requires proper setup and adjustment to ensure smooth operation.

- Limited Capacity:

- The number of tubes that can be stacked is limited by the feeder’s design.

- Component Size Restrictions:

- The feeder may not be suitable for very large or irregularly shaped components.

-

Conclusion

The FUJI Horizontal Stacked Tube Feeder is an essential tool for feeding components supplied in tubes, such as ICs and connectors, in automated PCB assembly lines. Its stacked design, high-speed operation, and seamless integration with FUJI pick-and-place machines make it a reliable and efficient solution for SMT production. If you need more details about specific models, configurations, or suppliers, feel free to ask!